Engineering Design & Manufacturing

Industrial Laser Solutions

High Efficiency & Performance

Silicon carbide, ceramic, and glass substrates in high-power industrial laser applications can operate at much higher voltages, frequencies, and temperatures than traditional silicon-based components. The choice of laser scribing is critical for AI and EV applications.

Precision Engineering

The hardness and subtlety of new substrates make it challenging to scribe without inducing defects, microcracks, or chipping, and vulnerable to a Heat-Affected Zone where the material properties are altered. Precision engineering and thermal management are crucial.

Increased Durability

Electrical Steel: Laser Magnetic Domain Refinement is like a micro-surgery for electrical steel using lasers to optimize grain structure and reduce domain wall pinning sites, slashing core losses in transformers and motors by up to 15%, translating to the efficiency of power transmission and distribution of motors, generators, and transformers.

Precision laser welds offer superior strength, heat control, and minimal distortion compared to traditional methods, leading to more efficient, longer-lasting motors and transformers.

Direct Metal Deposition: Lasers build 3D metal structures layer by layer, enabling the creation of complex, high-precision parts impossible with traditional methods.

Laser Ablation: Precisely remove or reshape materials at the microscopic level, ideal for creating intricate features in parts like ABS solenoid valves or microfluidic devices.

AIEV Laser: Advanced laser scribing technology of next-generation substrates like SiC, ceramic, and glass, to meet the high-voltage, high-temperature, and high-frequency applications to AI semiconductors, data centers, and EV applications.

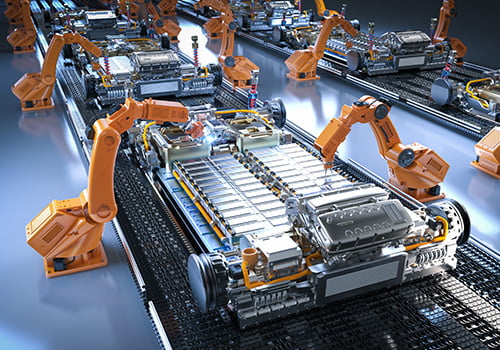

Battery Collector Surface Treatment: Ultra-fast laser pulses are now used to improve rechargeable batteries, resulting in an increase of electrode capacity by up to 60% and a lifetime extended by 30% by modifying the surface property of the current collector.

Battery Spot Welding: Creates strong, localized welds without damaging sensitive battery components, crucial for reliable and safe battery packs.

Engineering Design

High-precision welding and surface treatment of aircraft, automotive, electronics, and medical devices

Automation

Precise, high-speed tasks with minimal human intervention, including cutting, welding, drilling, and marking materials with consistent accuracy

Improved Productivity

Superior precision, minimizing defects and ensuring consistent product quality, boosting productivity.

Cost Saving

Faster processing speed, while minimizing material waste through precise cutting and ablation techniques, reducing maintenance costs.

Engineering Projects & Manufacturing

Industrial Laser Machining

Projects

Engineering Design to Manufacturing of Industrial Laser Solutions

Improved Quality & Safety | Lower Maintenance Cost.

Improve Core Loss & Production Yields | G3 LMDR

Wafer defects diagnostics | surface treatment

Communication module laser cutting and welding

Ceramic laser perforator and scrubber

Motors, battery, airbag, ABS solenoid value, high-precision parts manufacturing | Improved costs & productivity

LCD platinum platinum laser cutter | Glass surface treatment.

Non-invasive 3D real-time imaging | 10~30 times higher resolution than MRI, PET, CT Scan