AIEV Laser Solutions for Power Electronics

AIEV Laser offers next generation laser scribing solutions in high-voltage, high-temperature, and high-frequency application like advanced AI Semiconductors, and EV applications.

Silicon Carbide (SiC)

SiC can handle higher voltages and faster switching speeds than silicon, making it ideal for high-power, high-temperature, and high-switching frequency applications, and allows for smaller, lighter, and more efficient components.

The challenges are SiC is hard and brittle, requiring high-precision non-contact methods like custom laser scribing technology to avoid material damage during processing.

Ceramics Substrates

Ceramics provide excellent thermal stability and insulation, making them essential for packing high-power devices that generate significant heat.

Ceramics are hard but brittle, prone to cracking during mechanical processing, which require precise and proven laser scribing technologies to avoid damage.

Glass Substrates

Traditional silicon-based integrated circuits (ICs) have long been foundational to the development of power electronics. Still, as the demands on these systems increase in terms of efficiency, power density, and thermal management, several challenges arise. Advancement in laser scribing technology offers innovative solutions to these challenges.

Thermal Management : Silicon has a limited ability to dissipate heat generated during operation. This thermal limitation restricts the power density that can be achieved and impacts the reliability and longevity of the devices.

Switching Speeds and Efficiency: Silicon devices have intrinsic material limitations that affect their switching speeds. Faster switching speeds are desirable in power electronics as they improve efficiency and reduce energy losses but can also lead to increased electromagnetic interference and switching losses.

Material Breakdown at High Voltages: At high voltages, silicon devices are prone to breakdown and other reliability issues. This necessitates the use of more complex designs, such as thicker layers and protective coatings, which can complicate manufacturing processes and increase costs.

Advanced AIEV Laser scribing technology can improve the manufacturing and operational characteristics of the next-generation substrates for advanced power electronics, and effective HAZ management.

Precision Dicing and Scribing: AIEV Lasers can precisely scribe and dice silicon wafers, allowing for the creation of smaller, more tightly packed components. This precision can be crucial for improving the integration density of power circuits.

Benefits: Reduces material waste and enables complex geometries that are difficult to achieve with traditional mechanical cutting methods.

Thermal Isolation and Management: AIEV Laser scribing can be used to create isolation trenches or modify the surface of silicon to improve its thermal properties.

Benefits: Enhanced heat dissipation capabilities by structuring the substrate to facilitate better thermal management, potentially increasing device reliability and performance under high-power conditions.

Creating Low-Resistance Pathways: AIEV Lasers can modify the conductivity pathways within silicon substrates by altering the dopant profiles or creating specific microstructures.

Benefits: Optimizes the efficiency of current flow, potentially reducing resistance and power losses.

AIEV Laser Technology

A New Standard for Next-Generation Substrate Processing <a class="glossaryLink" aria-describedby="tt" data-cmtooltip="<div class=glossaryItemBody><!– wp:paragraph…

Critial Role of Laser technology in advanced material processing

Laser technology plays a critical role in the manufacturing and processing of advanced materials such…

Why SiC Wafers Are Important?

What is a Silicon Carbide (SiC) Wafer? Silicon Carbide (SiC) wafers are semiconductors composed of…

Key Requirements for Laser Scribing Technology in High Thermal Semiconductors

As semiconductors for AI applications and electric vehicle (EV) components become more advanced, the need…

The Rise of Next Generation Substrates for High Power Electronics

The Rise of New Substrates for High-Power Electronics and How to Select Laser Scribing Technology…

Sic Laser Scribing

Silicon Carbide (SiC) Laser Scribing has become increasingly crucial in the semiconductor industry, particularly with…

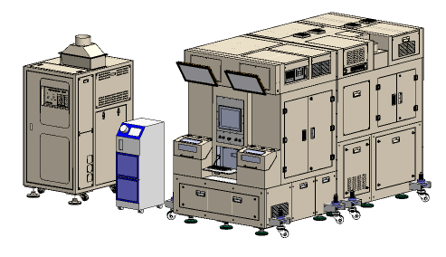

AIEV Laser Scribing

High-precision laser scribing on SiC, Glass, and Ceramic substrates

Automation

Precise, high-speed tasks with minimal human intervention, including cutting, welding, drilling, and marking materials with consistent accuracy

Improved Productivity

Superior precision, minimizing defects and ensuring consistent product quality, boosting productivity.

Cost Efficiency

Faster processing speed, while minimizing material waste through precise cutting and ablation techniques, reducing maintenance costs.

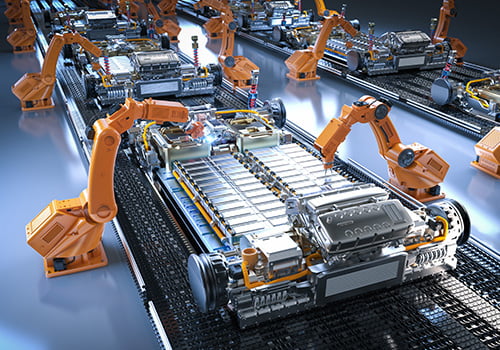

AI and EV Applications

AIEV Laser Solutions

AIEV Laser Scribing

Customized Design to Manufacturing for AI semiconductors and EV Applications

Improved Quality & Safety | Lower Maintenance Cost.

Improve Core Loss & Production Yields | G3 LMDR

Wafer defects diagnostics | surface treatment

Communication module laser cutting and welding

Ceramic laser perforator and scrubber

Motors, battery, airbag, ABS solenoid value, high-precision parts manufacturing | Improved costs & productivity

LCD platinum platinum laser cutter | Glass surface treatment.

Non-invasive 3D real-time imaging | 10~30 times higher resolution than MRI, PET, CT Scan

Need Help with Innovative Industrial Solutions? Contact Us!

Laser Scribing Solutions | Nest-Generation Substates

Experience The Power of Collaboration

Forging Innovation Together

Our success story isn’t just about groundbreaking technology, it is about harnessing the power of collaboration. From the initial spark of design to the craftmanship of manufacturing, we stand shoulder-to-shoulder with our clients, tackling challenges and forming solutions together.